About Us

Expert Craftsmanship & Timeless Beauty

Expert Craftsmanship & Timeless Beauty

The art of timber framing has been around for thousands of years. It was the primary way homes were constructed from the early centuries AD in both Europe and the Orient. Early civilizations built this way because timber frame homes don’t just last a lifetime—they last generations. From large barns in the countryside to the family homes in the coastal villages of New England, solid beams and peg and socket joinery created the bones of buildings that would last centuries.

Timber Frame is a refined wood building style that utilizes heavy timbers with interlocking wood-to-wood, mortise and tenon joinery and fasteners rather than nails, screws, or metalwork. Unlike conventional stud framing that’s most common today, timber frame homes leave the timber post and beam supports exposed to be seen and admired, creating an architectural element that often blends in with its natural environment. Not only are timber frames aesthetically beautiful, but you also get the very best of structural soundness. With the technology we have today, we go even further in creating precision-crafted joinery that is solid, stable, and of lasting beauty.

Building green with sustainable materials is becoming more significant with the growing concerns of climate change and energy independence. Timber is one of the only renewable resources used in construction because of tree regrowth and with a carbon footprint that’s 75% less than that of concrete or steel, it’s no surprise that wood has become a top contending material for green builders. Wooden structures absorb and store atmospheric CO2 for as long as the building stands or the timber is used.

Additionally, it takes very little energy to convert trees in to a usable product. The embodied energy in timber is extremely low compared to most common building materials.

Airtightness & Insulative Integrity

Many builders will tout their use of solar panels, geothermal heating/cooling systems, or their heat exchange air-filtrations systems, all of which we endorse and are wonderful for your home, yet the single most important element of an ecologically sound home is the airtightness and insulative integrity of the home’s “enclosing envelope,” or shell. With conventional building today, where walls are framed and filled with insulation, and then dry-walled, the envelope is rather porous. No matter how high the R-value of the insulation, if cold and heat are penetrating the cracks, homes will be less efficient.

Our timber frame structures are commonly wrapped in structurally insulated panels (SIPs) to achieve a high performing weather-tight shell. Want to learn more about SIPs?

Located on the Front Range of the Rocky Mountains, our 30,000 square foot facility is equipped with the most advanced automated Hundegger CNC joinery and planning machinery called the K2i. This CNC machine provides the most versatile and accurate joinery available reducing costs, waste, and increasing efficiency. It is equipped with the widest timber track in the industry and its modular system can accommodate member sizes up to 24”x48”x60’. In addition to our CNC machine, we possess a Woodmizer sawmill, Hundegger HM-D planer, in-house texturing and finishing equipment, and sit on six acres of timber inventory.

Our centralized location outside of Denver, Colorado allows us to produce and ship timber frame packages across the United States and North America quickly and at affordable rates.

If you’re building a timber frame home or structure, we invite you to take a tour of our facility to see how our timbers are cut, finished, and packaged.

You’re finally at the stop dreaming, start doing stage. So now what? Whether you’re building a timber frame home, barn, or outdoor structure, there are a few things you can do to prepare for your initial discussion with a Colorado Timberframe representative.

1) Gather Images and Floor Plans

We recommend gathering as many inspirational images and floor plans that match the layout, function, and personal style you desire. Helpful resources may include magazines and websites such as Pinterest, Instagram, and Houzz.

2) Create a “Wants” and “Needs” List

While gathering images and floor plans, create a list of what features are necessary for the layout and function of your home based on your lifestyle needs, both now and in the future. For example, if you’re an outdoor enthusiast, then you will want a space to store equipment. If you’re planning to live in this home as you age, consider a floor plan with a master bedroom on the main level.

3) Acquire Land

This is also the time to start researching available land and the associated building costs in the area so you can begin establishing a budget for your project. The location of your property and characteristics of your site will directly influence the design of your project.

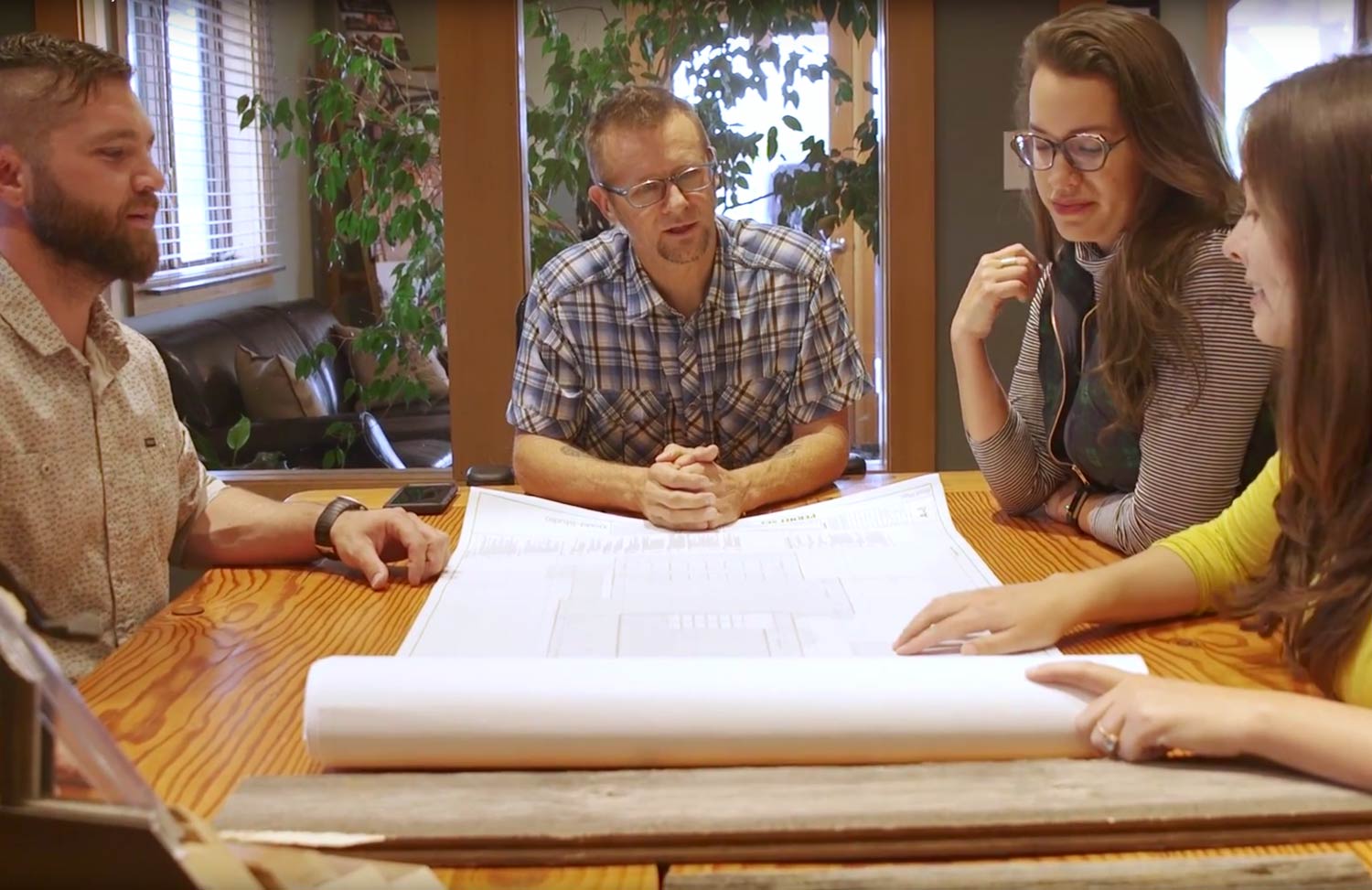

When scheduling an initial consultation with Colorado Timberframe, an appointed representative from our team will guide you through our services, giving you the ability to decide what design path and construction solutions are best suited for your project needs.

Once we have an understanding of your project goals, we can start building a team of professionals who will be highly involved in the success of your project, from start-to-finish.

Whether you choose to start with a pre-existing design from our collection of floor plans or create a custom design from scratch, Colorado Timberframe provides a full range of architectural design services through our associated licensed architects. Our architects provide services that meet the functional, financial, and aesthetic needs of our clients and will provide consultation throughout the jungle of decisions during the process. Alternatively, if you’re already working with an architect, we are happy to join forces with them to integrate the timber frame design into the existing architectural plans.

It’s also important to hire a general contractor as early on in the design process as possible so they can weigh in on the local costs associated with the design. Your builder or general contractor will manage the project’s overall budget and scheduling from site prep to finish work. Ask us if we have a preferred builder in your area!

There are three stages in the design process that you will work through with our architect to achieve the perfect layout and visual style.

There are many variables that influence the cost of your timber frame package.

Cost factors:

1) Volume of Timber

The size of your project is the most influential variable because it impacts the amount of material that is need. A hybrid timber frame, making the choice to do part of the home timber frame and part as stick building, can make a project more affordable. With a hybrid package, you can locate a structural, self-supporting timber frame in the main living areas of the home and build the wings (bedrooms) with SIPs.

2) Timber Selection

Just like there’s a ‘good, better, best’ option for your cabinets and hardwood flooring, there are also different levels of timber. Pricing can vary greatly depending on the wood species, growth pattern (grading), and the method in which the material is dried. Some timber frame companies use Southern Yellow Pine or “green” lumber which provides a lower initial cost, however, has many disadvantages and can cause both structural and aesthetic complications resulting in future costs.

3) Location

If you’re building at a high elevation, you’ll be working with a greater snow and wind load which could result in larger member sizes or steel reinforcement to meet specific engineering requirements. Additionally, climate zones determine the SIP insulation value required by building codes. For example, your walls can have a lower R-value in a mild climate than that of a colder climate.

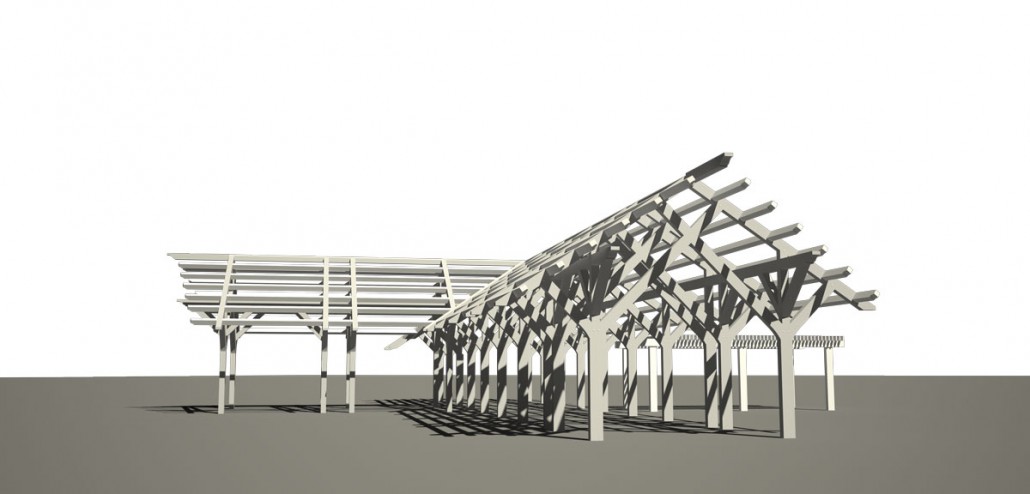

4) Design Complexity

Simplicity saves, complexity costs. Curved timber cuts, embellished drop heads or corbels, and detailed trusses with a lot of joinery will drive costs up due to waste factor and fabrication time on our machine.

5) Angles and Roof Lines

Square and rectangular shaped spaces are easier to build and lend well to timber frame design.

Beyond the timber frame package, many of your design choices will affect the overall turnkey cost of your project. There are endless choices when it comes to finish options such as appliances, cabinets, and lighting fixtures. Your builder will provide you with an allowance or options list to keep your project in line with both your budget and unique style. Additionally, different geographic economies create variances in the average cost of labor and local materials. The average cost to build in some areas of the United States may be as little as $150/SF or as much as $600/SF.

Each project goes through a detailed shop drawing review process that includes all structural engineering calculations and professional engineering stamps on structurally related drawings for the timber frame and SIPs. This process checks for accuracy on:

Once shop drawings are approved, we can schedule your frame in our production queue. To reduce any errors during fabrication, we run a test piece through our machine between each project to confirm that the calibration is set correctly before we move to the next project. Our timbers are all pre-drilled, pre-cut, and hand-sanded at our facility so that there’s no extra onsite work needed for assembly. Similarly, our SIPs are pre-cut for accuracy with electrical chases, insulated headers, embedded nailers, and hardware included.

Once your package is ready to be shipped, we label, sticker, and securely wrap the timbers onto shipping pallets prior to leaving our facility.

As we continue to grow as a timber frame package provider, Colorado Timberframe is looking for partnerships with general contractors across the country with whom we can efficiently and harmoniously build timberframe homes. Having been in this industry for two decades, we know the ins and outs of what builders face for each project, and we are primed to help you provide the best building experience for your homeowners.

When we enter a jobsite with you, we are not simply an independent third party, we are vested in your interests and committed to improving your reputation. If you look good with your clients, so do we. Our philosophy is to partner with you, not only to sell our packages and services, but to build impeccable reputations through lasting relationships.

This is one of the reasons we offer such a wide variety of packages and services. Whether you need a frame or a complete enclosing shell, a design team or an architect, or if you need anything from a supervisor to a complete installation crew, we have the right technology and people to do the job right and keep your clients happy. We are flexible and want to work within the parameter of your unique system and set budget for each home you are building.

Although we are comfortable with jumping in at any point in the process, we have found the sooner we can start working with you, the more our experience can help. Success for any project is often determined by getting the details right, and we have been doing this long enough to know what those details are. So whether you are a seasoned timberframe contractor or new to the game, we want to put our expertise to work in partnership with you.

We understand how critical the role of an architect is for any home project, and it is even more so for timber frame homes. We know that it is not just a question of the aesthetics that timber frame mortise and tenon offer, but a process of truly integrating the structural strength of timber frame posts and beams with the beauty of the natural woods that draw homeowners to want timber frames in the first place. It is in the integration of the strength and various artistic joints and pegs and aesthetic elements that make each home a statement of the families they are built for.

You can contact us at any time in the process, but we have found the best benefit we can provide to architects is as soon as the schematic design is done. This allows us to align the components in our timber frame package with your architectural package—creating an interactive design process that combines our knowledge in timber frame structure with your design expertise. Our goal is to develop a package for your client that is beautiful from the “bones” out. We are equipped to interface with any design software, whether it is CAD, Revit®, SketchUp, Mac-based, PC-based, 2-D, or 3-D. We can turn around quotes or produce packages to produce timber frame houses according to your specifications.

The Architectural Campaign

Colorado Timberframe is in the process of planning the manufacturing of at least 30 to 40 luxury homes ranging from 1,500 – 15,000 square feet each year. We plan to expand this pace in the coming years. Because of this, we are always looking to partner with the most highly recommended architectural firms throughout North America who are as passionate about timber frame artistry as we are.

Once a partnership is formed, Colorado Timberframe will recommend your architectural services to clients who approach us looking for help with designing their timber frame home. As part of this collaboration, we also hope to bid, produce, and build luxury timber frame homes for your clients who find interest in timber frame. We hope to combine respective talents and strengths to create a dynamic and prosperous synergy with each of our partners that will last for years to come.

“As principal of Foreshew Design Associates Inc., I thoroughly enjoy working with Colorado Timberframe. Having worked with multiple heavy timber manufacturing companies in the past I can truly say that Colorado Timberframe is among the top in their league. Colorado Timberframe has an amazingly skilled sales and design team that help guide their clients vision all the way through the design stage and see’s it through even after the last timber is pegged in place on your property. This team is friendly, knowledgeable and highly skilled in the art of true heavy timber framing and their attention to detail and care for spectacular architecture is second to none.

Mixing old world timber framing methods with cutting edge technology such as CNC precision is a true indicator that Colorado Timberframe cares about delivering the highest quality end product to their clients. I highly suggest if you are looking to involve true beauty into your new home or vacation getaway that you get in contact with Keenan Tompkins, Owner & President of Colorado Timberframe and his great sales staff. You will not be disappointed!

Our firm looks forward to working closely with Colorado Timberframe and their amazing project team on spectacular projects for years to come.”

“Colorado Timberframe are experts in the craft of true timber frame design and construction. As architects, we have worked with Colorado Timberframe on several projects and are always impressed with their knowledge and attention to detail. With the ability to fabricate any design conceived in their local shop, their pricing is competitive and the design options almost endless. If you are interested in timber frame as part of your project, we would highly recommend Colorado Timberframe.”

“The owners are absolutely amazed! The amazing work that took place in Colorado made this all fit like a glove.”

“As a material supplier, being the first time doing business with Colorado Timber Frame has been an enjoyable and successful venture. From the first phone call with my northeast Colorado Timberframe representative and with speaking with CTF office staff, to the last delivery made, the professionalism shown and given to the employees of Giarrusso Building Supplies and myself was exceptional. Whether a material supplier or potential home buyer, I would not hesitate recommending Colorado Timber Frame, and look forward to doing business with them in the future.”

“Truly professional team of leaders. As a subcontractor it was a pleasure and a true joy to work with a team that prides itself on such quality, pride, and a true work ethic! It would be our pleasure to work with you in the future.”

https://www.coloradotimberframe.com/wp-content/uploads/2020/02/CornerstoneHomes_Magnolia_Aerial-West-Elevation-AM.jpg

975

1464

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2022-06-15 16:26:072022-06-15 17:20:57Building a Timber Frame Home in a Remote Location

https://www.coloradotimberframe.com/wp-content/uploads/2020/02/CornerstoneHomes_Magnolia_Aerial-West-Elevation-AM.jpg

975

1464

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2022-06-15 16:26:072022-06-15 17:20:57Building a Timber Frame Home in a Remote Location https://www.coloradotimberframe.com/wp-content/uploads/2021/03/HAP5940-2.jpg

667

1000

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2021-03-31 16:36:502021-03-31 20:33:21Colorado Manufacturing Awards 2021 Finalist

https://www.coloradotimberframe.com/wp-content/uploads/2021/03/HAP5940-2.jpg

667

1000

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2021-03-31 16:36:502021-03-31 20:33:21Colorado Manufacturing Awards 2021 Finalist https://www.coloradotimberframe.com/wp-content/uploads/2020/12/DSCN2965.jpg

1125

1500

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2020-12-01 16:57:242020-12-02 12:57:44Explained: The Difference Between Timber Frame and Post & Beam

https://www.coloradotimberframe.com/wp-content/uploads/2020/12/DSCN2965.jpg

1125

1500

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2020-12-01 16:57:242020-12-02 12:57:44Explained: The Difference Between Timber Frame and Post & Beam https://www.coloradotimberframe.com/wp-content/uploads/2020/11/COTF_Breck-Haus_great-room-1.jpg

1000

1500

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2020-11-10 12:12:252020-12-01 15:47:45Why Choose Timber Frame For Your Vacation Rental

https://www.coloradotimberframe.com/wp-content/uploads/2020/11/COTF_Breck-Haus_great-room-1.jpg

1000

1500

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2020-11-10 12:12:252020-12-01 15:47:45Why Choose Timber Frame For Your Vacation Rental https://www.coloradotimberframe.com/wp-content/uploads/2016/09/5-High-Res-e1546019668271.jpg

900

1200

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2020-07-08 14:36:172020-12-01 15:46:504 Common Elements Found in Mountain Modern Timber Frame Homes

https://www.coloradotimberframe.com/wp-content/uploads/2016/09/5-High-Res-e1546019668271.jpg

900

1200

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2020-07-08 14:36:172020-12-01 15:46:504 Common Elements Found in Mountain Modern Timber Frame Homes https://www.coloradotimberframe.com/wp-content/uploads/2017/06/smBackporch-8.jpg

865

1296

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2020-04-30 13:37:122020-12-01 15:48:18Maintenance For Your Timber Frame

https://www.coloradotimberframe.com/wp-content/uploads/2017/06/smBackporch-8.jpg

865

1296

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2020-04-30 13:37:122020-12-01 15:48:18Maintenance For Your Timber Frame https://www.coloradotimberframe.com/wp-content/uploads/2019/11/Screen-Shot-2019-11-11-at-12.05.11-PM-e1573495976699.png

551

1000

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2019-09-30 10:11:552020-12-01 15:52:32Timber Frame 3D Model Fly Through

https://www.coloradotimberframe.com/wp-content/uploads/2019/11/Screen-Shot-2019-11-11-at-12.05.11-PM-e1573495976699.png

551

1000

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2019-09-30 10:11:552020-12-01 15:52:32Timber Frame 3D Model Fly Through https://www.coloradotimberframe.com/wp-content/uploads/2018/12/20180718_070212-e1545110895152.jpg

563

1000

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2018-12-17 21:46:212020-12-01 15:48:54An Off-Grid Timber Frame Ski Hut

https://www.coloradotimberframe.com/wp-content/uploads/2018/12/20180718_070212-e1545110895152.jpg

563

1000

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2018-12-17 21:46:212020-12-01 15:48:54An Off-Grid Timber Frame Ski Hut https://www.coloradotimberframe.com/wp-content/uploads/2018/04/CARIBOURIDGE_02.16.17_Exterior1.jpg

1378

2968

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2018-04-12 14:37:542020-12-01 15:49:33A New Timber Frame Home Community in Colorado

https://www.coloradotimberframe.com/wp-content/uploads/2018/04/CARIBOURIDGE_02.16.17_Exterior1.jpg

1378

2968

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2018-04-12 14:37:542020-12-01 15:49:33A New Timber Frame Home Community in Colorado https://www.coloradotimberframe.com/wp-content/uploads/2016/08/Sonoma_9206_Sparrow_Hawk_FRO7832_20160629-760x507.jpg

507

760

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2016-08-05 14:05:062020-12-16 12:45:47Modern Mountain Timber Frame in North Carolina

https://www.coloradotimberframe.com/wp-content/uploads/2016/08/Sonoma_9206_Sparrow_Hawk_FRO7832_20160629-760x507.jpg

507

760

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2016-08-05 14:05:062020-12-16 12:45:47Modern Mountain Timber Frame in North Carolina https://www.coloradotimberframe.com/wp-content/uploads/2016/08/Colorado-Timberframe-IMG_1432.jpg

400

600

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2016-07-25 09:35:062020-12-14 14:29:26Youth Retreat on Minnesota Lake

https://www.coloradotimberframe.com/wp-content/uploads/2016/08/Colorado-Timberframe-IMG_1432.jpg

400

600

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2016-07-25 09:35:062020-12-14 14:29:26Youth Retreat on Minnesota Lake https://www.coloradotimberframe.com/wp-content/uploads/2016/04/Kitchen.0034.jpg

854

1200

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2016-04-25 15:49:582020-07-17 10:59:03A Timber Frame Design Inspired by Nature

https://www.coloradotimberframe.com/wp-content/uploads/2016/04/Kitchen.0034.jpg

854

1200

Michelle

https://www.coloradotimberframe.com/wp-content/uploads/2018/08/colorado-timberframe-nav_logo-2018-grey.png

Michelle2016-04-25 15:49:582020-07-17 10:59:03A Timber Frame Design Inspired by Nature